Used Industrial Robots

Find used industrial robots!

Last Updated: February 11, 2023

Used Industrial Robots For Sale

Are you looking to purchase a used industrial robot? Multiple companies throughout the United States supply refurbished robots that are now just like new robots. There has been significant growth in the second hand robots market as more companies look for automated processes due to labor shortages worldwide.

Benefits Of Purchasing Refurbished Industrial Robots:

-

Robot Cost Savings

The cost savings can be massive depending on the number of robots purchased. Customers can buy robots about 50% cheaper than brand-new ones.

-

Production Flexibility

If this is the first system in a facility, the company will not have to worry about training employees on new tasks, and programmable logic controllers can change the automated robotic process to the following product. This makes part changeovers extraordinarily flexible and easy to move between products than manual, labor-intensive processes.

-

Robot Upgrades

If a robot has been in use for thousands if not millions of working hours, most likely, customers can find a similar robot with hundreds of working hours to replace older and run-down robotic systems. A used robot system will allow the customer to find the same robot controller, teach pendant, model, or power supply currently operational.

-

Robot Spare Parts

Buying spare parts was much easier and cheaper. Used robot suppliers will have lots of spare parts that they can use from other on-site systems.

-

Ease Of Integration

The advantage of the customer’s technicians and engineering staff having some familiarity with the robotic systems allows for easier integration, robot programming, and equipment maintenance. If the system has been operational for years, the operators and technicians will be comfortable with a used robotic system because it is exactly like the old one. Your engineers can quickly set up and robot program the facility for faster integration. The employees will also know the preventative maintenance requirements to keep the robotic system in its best operation.

-

Robot Warranty

Many used robot suppliers provide warranties on their robots. Customers can purchase articulated robots knowing they will have the confidence to work just like new ones.

-

Robots Are In-Stock

Many manufacturing brands have a waiting list of over a year until the customers can receive their robots. Many used robot suppliers have stock now of what customers may be looking for, so the lead time is cut to weeks instead of months until they would receive the robots.

-

Robot Manuals and Documentation

Many robotic equipment suppliers can provide the manuals and other documentation that come with the robot. The great thing with used robots is the manuals have been updated with the latest revisions and are radially available to share with customers.

Used Industrial Robot Companies:

Below we list our top companies to purchase used robots and robotic equipment.

R.A.B. Industries, Inc.

Location: Michigan

Types of Robots Available:

- Fanuc

- ABB

- KUKA

- Nachi

- Panasonic

R.A.B. Industries, Inc. is a full-service automation machine tooling dealer, liquidator, and auction company. They offer consignment, brokerage, auction, plant liquidation, and appraisal services. They work with many manufacturing companies to buy and sell robotic equipment. With 30 years in the robotic industry, they have become robotics and automation equipment specialists.

Robots Done Right

Locations: Ohio, Florida

Types of Robots Available:

- Fanuc

- ABB

- Motoman

- Universal Robots

- KUKA

Robots Done Right provides customers with robots and robot parts. They bulk purchase robots worldwide to deliver high-quality robots to their customers. They sell used as-is and refurbished robots. They also have a vast network to find specific robots customers might request.

HRG Industrial Surplus

Location: Michigan, Ohio, Alabama, Texas, Wisconsin

Types of Robots Available:

- Fanuc

- ABB

- Kawasaki

- KUKA

- Denso

HGR has a vast inventory of used industrial robot equipment. They will buy and sell used industrial surplus equipment. HGR has a large team throughout the United States that inspects equipment before purchase. They have an extensive inventory catalog on their website and many facilities.

Tennessee Industrial Electronics

Location: Michigan, Tennessee

Types of Robots Available:

- Fanuc

TIE specializes in Fanuc robots. They perform an in-depth refurbishment process that consist of a thorough inspection process. After inspection, they run a full range of motion repeatability/durability test for at least ten hours with a full payload. Another inspection is performed after the durability test of electrical and mechanical components to ensure the refurbished robot meets all quality control standards.

Trustworthy Robot Automation Companies:

Robot professionals

These companies have +10 years of industry experience in refurbishing robots.

Quality Robots

Robot warranty packages are also available for most of the robots sold.

Certified Robots

Maintenance procedures are performed to ensure the robots are in top performance when introduced to the assembly line.

Used Industrial Robot Cost Savings:

The main reason to buy a used industrial robot is the cost savings over a brand-new industrial robot. These used or refurbished robots are significantly less expensive than a new model. The average used robot costs about 50% less than a brand-new robot.

The savings a small to medium size business can make is quite significant after purchasing even two or more robots. Companies that need to be budgetary conscious should highly consider buying a used robot.

These slightly used robots often have low hours and can perform their robotic automation tasks at the same rates as new robots. With a lower initial capital investment, the company will see a quicker return on its investment than if they were to purchase a brand-new robot.

How to buy a used industrial robot?

Many factors go into buying a used or refurbished industrial robot. These factors include:

- Budget

- Payload

- Reach

- Work Envelope

- Application Type

- Robot Type

These listed items can establish these factors before purchasing, but the robot dealer can assist with setting a customer’s needs based on their specific criteria.

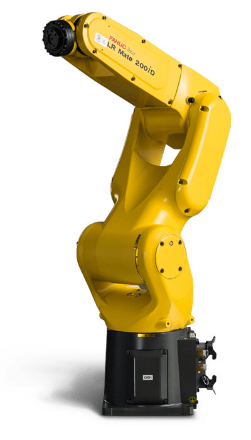

Buy Refurbished FANUC Robots:

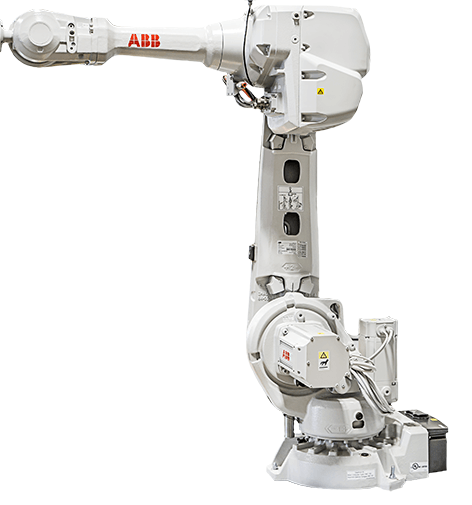

Buy Refurbished ABB Robots:

Buy Refurbished MOTOMAN Robots:

Buy Refurbished NACHI Robots:

Buy Refurbished KUKA Robots:

Buy Refurbished KAWASAKI Robots:

Why buy a used industrial robot?

Buying industrial robots is more readily available than ever! Refurbished articulated robots are now very affordable and ready for production use once they arrive on-site. Most likely, the competition has industrial automation throughout their facility, so manufacturing companies must automate their processes to keep up with competitors.

Lead times to purchase new robots are currently astronomical and can jeopardize the project’s start of production timeline. Customers can also find robots domestically without worrying about expensive overseas shipping costs or the possibility of even longer delays.

Buying used or refurbished robots allows customers to visit their purchased robot before installation. They can see that the robot is in working condition and is ready for the production floor. Generally, these places have plenty of robots to choose from, so most likely, they will have what you are looking for, or they can find it.

These robots will be a reliable factory automation solution for your business. Even if a robot has been in operation for many years, it can be back in the automated process for several more years if it has lower run hours. Having a robot that is a new verse used is sometimes difficult to tell after installation because they are just as reliable and usually get just as dirty after a few weeks.

Used robots are quality equipment with new parts, fresh grease, and new paint. When purchasing a refurbished robotic system, you will be happy to know that the entire system will operate correctly because of the vigorous testing and maintenance done to the equipment before shipping it to a customer’s facility. These robots will decrease production cycle times, reduce capital costs, improve the quality of products, decrease errors and keep people safe.

LEARN MORE ABOUT INDUSTRIAL ROBOTS:

-

What is an industrial robot?

An industrial robot is a robotic system often used in manufacturing. These industrial robots are programmed to perform functions that are often too dangerous for manual operators to execute or perform repetitive tasks that workers cannot compete with compared with automation.

-

Typical industrial robot applications.

- Assembly

- Visual Inspection

- Mechanical Deburring, Cutting, or Grinding

- Packaging or Palletizing

- Welding or Joining

- Dispensing

- Machine Tending

- Painting

- Material Handling

- Pick and Place

These functions are all highly proficient with extreme accuracy, endurance, and speed.

-

Industrial robot manufacturer brands.

Most robot resale providers will have the following robot brands:

- ABB

- FANUC

- MOTOMAN

- KUKA

- PANASONIC

- NACHI

- KAWASAKI

These resale providers will also have an abundance of different robot sizes. They will have more miniature tabletop robots with 2-5lb payloads or much greater payload robots that can carry hundreds of pounds on their end effector.

Four Main Types Of Industrial Robots:

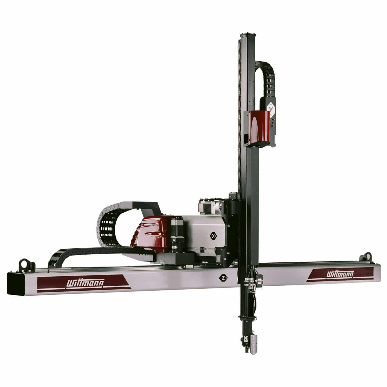

Cartesian Robots:

The cartesian robot system travels in three axes directions — X, Y, and Z, according to cartesian coordinates. On these gantry robots, A linear actuator is used on the axes of a cartesian robot system. These actuators are purchased from the manufacturer as a pre-assembled system or can be custom-built from the linear guide and drive components.

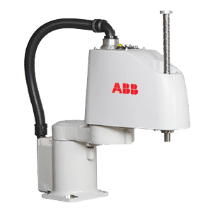

SCARA Robots:

The SCARA robot has a parallel-axis joint layout. This means the robotic arm is somewhat compliant in the X-Y path but firm in the Z direction. This allows the arm to reach into tight areas and pull back out of the way. This is beneficial for quickly transferring parts from one location to another or loading and unloading.

Delta (Parallel) Robots:

The delta robot consists of three primary moveable arms connected to common joints at the base of the arms. The primary design factor is the use of parallelograms in robotic arms. This is what maintains the positioning of the end effector.

Articulated (6-Axis) Robots:

The articulated robot has rotary joints called the axis. An articulated robot could be as simple as a two-axis with up to a complex ten-axis robot. Electric servo motors power these robot axes.

Most popular industrial automation categories:

-

3D CAD Modeling Software

Learn MoreFind the latest CAD modeling software for your automation project!

-

Robot Maintenance

Learn MoreLearn where to get preventative maintenance for industrial robots.

Stay Informed

Subscribe to our newsletter and get the latest automation news, trends, and topics in the industry.

I want the latest automation information

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Finding Automation LLC