Robot Programming Training Courses

Learn how to become a robot programmer!

Last Updated: February 17, 2023

Find Robot Programmer Training Classes!

Find great robot programmer training courses to enhance your career in automation. We have some tremendous hands-on robotics training programs listed in the United States. Robot programmer training classes generally last anywhere from one to five days, while other courses may last several weeks or months.

The need for robot programmers is on the rise, with industrial automation growing yearly and the labor force in the industry decreasing. It is a great profession that can be rewarding and beneficial for both company and the worker. Whether you are a recent high school graduate or looking for a new career in automation, the time is right to consider becoming a robot programmer.

Lots of companies are also giving robot training to their employees to upskill their workforce. This upskilling allows businesses to grow their internal resources to fill the skill gaps in automation. If your business is looking for locations to train robot programmers, our list of training facilities will be beneficial.

You can now find these classes all located in one spot. This article aims to help you find the best robot programmer training classes for your specific requirement.

Who needs robot programmer training?

- New Robot Programmers – Never used a robot before? No problem; sign up for a beginner robotics course, learn the basics of robot programming, and start your robotics career!

- Current Professionals – If you are in the industry and have never taken a course before, update your existing technical robot skills, so you know the ins and outs of your current robot.

- Experienced Programmers – Interested in learning how to program a new robot brand, or maybe your company is about to receive updated equipment? Learn how to use the equipment before it gets on the shop floor in an offline training cell.

- Expert Level – Continue your education, and challenge yourself to learn something new about the robot system that you did not know before.

The top 5 reasons to to become a robot programmer

Find out why you should be a part of this booming automation industry.

Basic Types Of Robot Programmer Classes:

Listed below are the types of classes that robot programming facilities will teach depending on the student's skill level.

- Beginner Robotics Course – These classes will teach basic programming functions, which include touching up points, editing or modifying programs, learning essential functions of the teach pendant, and some input or output signals. Students will also learn how to move the robot to safe positions and reset basic robot faults.

- Intermediate Robotics Course – Create programs from scratch, and program the tool center point (TCP). Learn how to program macros, set up robot zones, and adequately use input/out functions.

- Advanced Robotics Course – Advanced robotics training courses will specialize in critical areas of the robot process, either with specific tools and equipment added to the robot or on its key features.

What to look for in a robot training class?

-

Does a third-party resource accredit the class?

This involves a third-party certification from an independent provider that helps with the development and verification of the class. This third-party certification will help reduce conflicts of interest and provide significant meaning to a company’s training program. This third-party certification assessment is essential for any organization to help highlight its business to potential programming students.

The third-party assessment company will work closely with the robot training facility’s team experts to identify the key areas and critical abilities needed to become certified in each course level. The assessment company assists the training facility as the independent party in how students become certified. The assessment company's main reason is to ensure the training facility meets the minimum requirements of robot programming skills, determined by robot experts, to be successful in the automation industry.

Finding a training facility with NOCTI certification or assessed by another equivalent company would be recommended.

-

Do you get certified after completing the training?

A robot certification will indicate the student's skill level and knowledge of the robotic system. A certification program is focused on making students understand the essential robot functions of the program. The class should provide this documentation to the students, and it should identify the robotic course they took, the training provider, and the instructor's signature. The students can then add this certification to their resumes and professional portfolios.

-

Who is the robot instructor or subject matter expert?

A great instructor or subject matter expert can determine how well you learn and develop your robot programming skills. We recommend talking with each training facility about their robot curriculum programs. Please find out how long the instructors have been teaching and try to find out what the success rate is of their students who have taken the class.

It is essential to find out what materials you can take home after the class and what keynotes are provided with the robot training session. These robot instructors can be an excellent resource for students in the field, so see if you can connect with them once the class is completed; we recommend doing that.

-

What is the robot-to-student ratio in the class?

When investigating what training facility to select, it is essential to know the class size and the robot-student ratio. Ideally, you'd like to see a small classroom size with a 2:1 student-to-robot ratio. This allows for the maximum time students have with their hands on the teach pendant programming. Three people per robot teach pendant can also be effective for training, but we only recommend up to three students per robot.

-

What are the robot brands and models they provide training?

Finding a training facility with the same robotic equipment used in your facility is critical when trying to build your skills. Most training facilities use the latest robot brand equipment and software in their classes. Sometimes this does not correlate with older equipment the technicians may use daily in their manufacturing factors. Still, it is good to check with the training facility to make sure what they use for training purposes is equivalent.

-

What type of robot training class fits your skillset?

It is critical to find a training class that fits your programming skill. If you try taking a more advanced robot class than what you can perform, the course will be a waste. Some training facilities require students to take a test, or it may even have a prerequisite of taking a lower-level class first.

Hands-On Robot Programmer Training Courses.

Below we will describe our top robotics courses and schools for robot programmer training and why.

SKIP TO:

Advanced Automation Training Courses

Advanced Automation Training

Approximate Course Cost: $2,500.00

Training Facility Highlights:

Student-to-Robot Ratio: 1:1

Robots Ready for Training: 4

Robot Brands: Fanuc, ABB, KUKA

Number of Classes Offered: 5

Average Class Size: 3 max.

Accredited: No

Provided Certification: Yes

Site Location: Shelby Twp., MI

Advanced Automation Training Courses

PROS

- Robot-to-student ratio

- Smaller class size

- Postgraduate support program

- Great teachers

- Multiple robot brands available for training

CONS

- Limited number of seats in each class

This facility is great for one-on-one robot learning. The smaller class sizes are structured to have the students be teacher-focused while getting lots of hands-on training. The robot-to-student ratio is 1:1, giving students lots of time to learn about each robot during class.

They offer a postgraduate support program where students can reach out to teachers after class to ask questions to the group or instructor. A learning packet is provided to each student for them to keep notes and highlight memorable lessons learned.

Robotic Welding Training Courses

Lincoln Electric Training

Approximate Course Cost: $2,990.00

Training Facility Highlights:

Student-to-Robot Ratio: 1:1 to 3:1

Robots Ready for Training: 4

Robot Brands: Fanuc

Number of Classes Offered: 5

Average Class Size: <12

Accredited: Yes

Provided Certification: Yes

Site Location: Cleveland, OH

Lincoln Electric Robotic Welding Courses

PROS

- All students receive reference materials, documents, and contact information

- Free training with the purchase of a robotic system

- Robotic service training program

- WeldPRO class is a virtual meeting

CONS

- Potential of 3:1 student-to-robot ratio

- Entry-level exam is required before registration

- Only Fanuc robot training is available

According to Lincoln Electrical, more than 20% of commercial welding in the United States is done by robots. This trend is expected to grow as companies that use welding processes face a labor shortage in the manufacturing industry.

Welding robots will produce consistent weld quality, increase productivity, allow for product flexibility, and, most notably, are safe to use. Welding robots can be highly cost-effective if the robotic welding technicians are adequately trained in welding and robotics programming.

Lincoln Electric offers great robotic welding training programs. Their power supplies are matched with Fanuc robots, where students will learn about welding and how to program the robot.

Industrial Robotics Training

Industrial Robotics Training

Approximate Course Cost: $1,936.00

Training Facility Highlights:

Student-to-Robot Ratio: -

Robots Ready for Training: -

Robot Brands: Fanuc

Number of Classes Offered: 3

Average Class Size: 12

Accredited: Yes

Provided Certification: Yes

Site Location: Houghton, MI

Industrial Robotics Training Courses At Michigan Tech

PROS

- No prerequisite is required to attend the classes

- Provided with online modules before hands-on learning

- Certified Instructor

- Course content identical to Fanuc

- Well priced

CONS

- Isolated location

Michigan Tech offers multiple certified robot programmer training courses every fall and spring. One of the only places in the upper peninsula of Michigan to get robot programmer training.

Students will be given pre-test and post-test designed to determine attendees’ understanding of the course materials and track improvement. At the course completion, it is required to receive an 80% on the post-test to obtain the robot certification.

One of the downsides of this training program is that they are located in the upper peninsula of Michigan, so it can be challenging to travel to their training facility.

OEM Robot Training Courses:

Take a robot programming course directly from the original equipment manufacturer (OEM). Check out these links to set up your training course at the robot manufacturer. The OEMs often have very detailed courses on their systems and are meant for customers who purchase their equipment directly.

FANUC Robot Programmer Training

Yaskawa Robot Programmer Training

KUKA Robot Programmer Training

Kawasaki Robot Programmer Training

Robot Programming Colleges:

Are you interested in furthering your education? These colleges and tech schools offer college-level robotics or robot programming classes.

LEARN MORE ABOUT ROBOT PROGRAMMING

-

What is an industrial robot?

A robot is an extraordinary piece of industrial equipment that can sense its environment, then perform tasks based on computer decisions in the programmable logic controller (PLC).

Main components of an industrial robot:

- Sensors

- Actuators / Motors

- Motor Controllers

- Single Board Computer (SBC) / PC

- Microcontroller / PLC

- Power Supply / Battery

The three primary systems of an industrial robot:

- Intelligence – This part of the system helps the robot decide when to move and what task to accomplish. This is the brain of the robotic system and collects the data from external sources and processes this information into robot motion.

- Motion – The actuator motors do the robot joint movement, which is controlled by the motor controller that sends data to the microcontroller or PLC.

- Detection – Helps the robot identify its environment and relay the input back to the PLC. This is typically done using sensors, cameras, encoders, or lasers that interface directly with the PLC and PC.

-

What is robot programming?

Robot programming tells a robot to achieve a specific motion and report back to the PLC or PC through detection. These motions are performed using a robot teach pendant that drives the industrial robot to locations and tells the robot program what to do.

Robot programmers create a robot path for the robot’s motion to help make decisions in its robot applications.

-

Types Of Robotic Applications:

As a robot programmer, you could be asked to program many different types of applications that include:

- Adhesive / Gluing / Sealing

- Assembly

- Machine Tending

- Material Handling

- Mechanical Deburring / Cutting / Grinding

- Painting

- Pick & Place

- Packing or Palletizing

- Part Washing

- Welding / Mechanical Joining

- Visual Inspection

You want to discover what robotic applications you enjoy programming and find an employer with those types of robots. Each robot application is unique and requires a particular nuance to program.

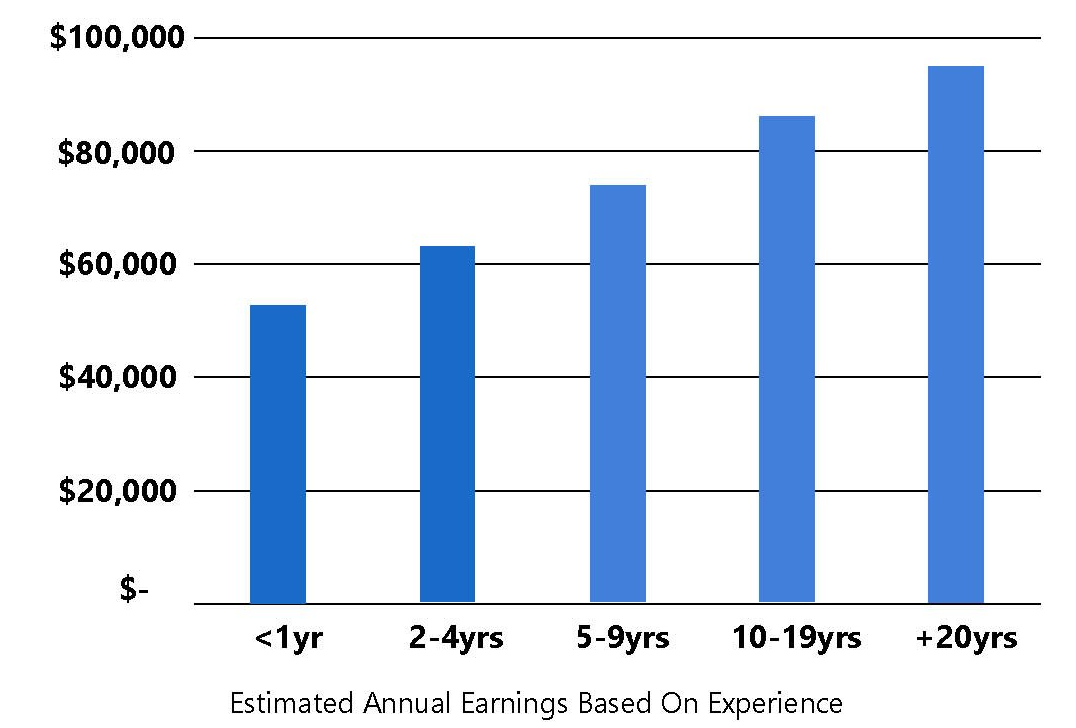

Robot Programmer Salary:

The average robot programmer’s salary in the United States is around $75,000 annually. This pay range for a robot programmer would be approximately $35.00/ hour or just over $6,000/month. The average robot programmer’s salary can vary quite drastically depending on the location of the job, the programmer’s technical skill level, and prior robot experience.

Robot Programmer Jobs:

There currently are lots of open robot programmer jobs throughout the United States. Here is a list of a few job titles that require robot programming experience:

- Robot Technician

- Robot Programmer

- Robotic Engineer

- Robot Maintenance

- Robotic Process Automation Development

- Robotics Software Engineer

- Automation Engineer

- Robotics Application Engineer

- Robotics Specialist

The great thing about robot programming is many technician, or maintenance jobs do not require a degree in the field. While there are many robot jobs listed above, some of the engineering or specialist roles may require advanced degrees to apply.

Working in automation will give you stability because you will have many job opportunities as the robotic automation and robot industry continues to grow. Many sectors are available for robot programmers to find jobs.

Many people find that contracting at the start of a career is very beneficial to gain a lot of robot experience. Places like JOINER Services offer robot programming jobs on their engineering service platform, giving contract robot programmers many opportunities to see many different client facilities, to build their programming experience quickly.

Sources: NOCTI, and Zip Recruiter.

Most popular automation training categories:

Stay Informed

Subscribe to our newsletter and get the latest automation news, trends, and topics in the industry.

I want the latest automation information

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Finding Automation LLC